A hose skimmer is a specialized device for removing oils, greases and other hydrophobic substances from the surface of liquids. This efficient and flexible separation device is used in numerous industrial applications to extend the service life of process fluids, reduce operating costs and protect the environment. Thanks to its innovative design, the hose skimmer can be easily integrated into various systems and is particularly suitable for areas that are difficult to access.

How a tube skimmer works

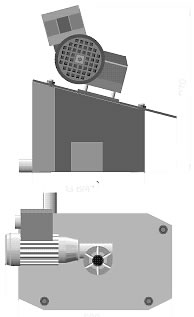

The hose skimmer works with an endless hose made of a special material that prefers to attract oily substances. The hose is immersed through a guide into the liquid to be cleaned and picks up the impurities floating on the surface. A drive motor ensures that the hose moves continuously through the liquid. The hose is then passed through a scraper, which removes the oil and grease from the hose. The separated oil is collected in a separate container where it is available for safe disposal or further processing.

Areas of application

Hose skimmers are used in a variety of industries, especially in metalworking where cooling lubricants are used. Here they prevent the accumulation of tramp oils and contribute to extending the service life of the coolant. They are also used in waste water treatment plants to remove oil films from water surfaces. Other areas of application include electroplating plants, machine washing systems, paint shops and petrochemical plants, where hose skimmers effectively separate oil and grease from process fluids.

A major advantage of the tube skimmer is its flexibility. The adaptability of the hose means that even areas that are difficult to access, such as narrow or low-lying tanks, can be cleaned effectively. This makes it an ideal solution for applications where conventional skimmers cannot be used.

Advantages of a tube skimmer

The hose skimmer offers a number of advantages that make it a preferred choice in many industrial processes:

- High flexibility: The movable hose can adapt to a wide variety of tank shapes and sizes and easily reaches hard-to-reach places that are inaccessible to other types of skimmer.

- Efficient oil separation: The special hose is designed to effectively attract and absorb oils and greases, resulting in high oil separation efficiency.

- Simple installation and operation: The hose skimmer is easy to install on various containers and is simple to operate. It does not require any complex adjustments and can be used flexibly.

- Low maintenance: Maintenance is limited to regular cleaning of the hose and the scraper device, which minimizes effort and costs.

- Cost savings: The reduction of impurities in the process fluids extends the service life and reduces the costs for replacement and disposal.

- Environmental protection: The separate collection and disposal of separated oils helps to reduce the environmental impact. The oil can be recycled or disposed of properly.

Disadvantages of a tube skimmer

Despite the many advantages, there are also some limitations when using a tube skimmer:

- Limited absorption capacity: With large quantities of oil or very thick oil films, the absorption capacity of the hose may be limited, which reduces efficiency.

- Regular cleaning required: The hose must be cleaned regularly to ensure optimum absorption capacity and to prevent blockages or deposits.

- Not suitable for all liquids: Hose skimmers are specifically designed for the separation of oils and greases and cannot effectively remove solid particles or chemical substances.

In summary, the hose skimmer is an extremely versatile and efficient solution for removing oil and grease from process fluids. Thanks to its flexibility and ease of use, it is indispensable in many industrial sectors and makes a decisive contribution to improving process quality and reducing costs and environmental impact.