Possibilities for Delivery

- high speed running

- slow speed running

- adjustable speed

- for pressure or vaccuum tank

- liquids very thin or high viscose

- with protecting flange

- with tighten flange

- with mechanical seal

- dry-run safe

- double mechanical seal without external liquid

- special shaft sealing ring up to 8 bar and high temperature, dry run safe too

Application

Application Simple mixing, saving mixing, mixing from high foam up liquids , solute from solids, homogenize, disperse, emulsify, heat exchange, aerating, circulate, neutralize, waste water treatment, electroplating included chemical nickel and chromic acid bath.

Possibility of Delievery

Special Desing

a) with hollow shaft and and available suction nozzle for pump over the tank (at the same time: mixing and pumping)

b) with venting wheel between drive and tank (at higher temperatures)

c) with pump nozzle below the drive, pipe to down to an atomize ring over the propeller, for inject carbonic acid for neutralition

d) with cutting knifes over the propeller

Drives

Electric motor, air pressure motor, hydraulic motor, all with or without explosion proofed ATEX, adjustable speed over hand wheel, adjustable over frequency converter, with different gears, without gear, partly one phase motors in accordance to ATEX, for mining to work underground too with fire damp protection, with bevel gear 90° between shaft and propeller for long lying tanks and vertical built-in.

Materials

PP, PVC, PVDF, PTFE (only with smallest agitators), steel, stainless steel 1.4541, 1.4571, hastelloy C

Agitators to come in many different designs, explostion proofe ATEX too

The picture are only very less samples, do you find YOUR agitator in any picture, don’t hesitate to contact us too if not.

of PP, specially micro perly air, with air flow shut-off too feature

with double mechanical seal and flange coupling

with grab handles, according to ATEX, with ring propeller and safety tube

acc. to ATEX, with centrifugal force propeller, with hollow shaft, suction nozzle below motor

of PP, carbonic acid nozzle below motor, injection over the propeller

with tank of stainless steel, with cross beam and lever clamping screw

with hollow shaft, shaft dismountable, without propeller, in ATEX too

very robust, with two lever clamping screws, for one or three phase

total made of PVDF, with sealing and bearing lantern, in ATEX too

with bearing lantern and two oblique blade stirrers, helical gear box

with distance lantern and sealing, adjustable speed by hand wheel

with splash ring, protective flange and 4-blade propeller

with 5 locking rolls, stroke adjustment by hand, mobile

mounting by anchor bolts, stroke adjustment by hand, with counter weight, adjustable speed

mounting by anchor bolts, stroke adjustment by hand, with counter weight

by hand to reverse: stirring or pumping

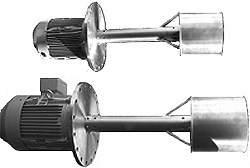

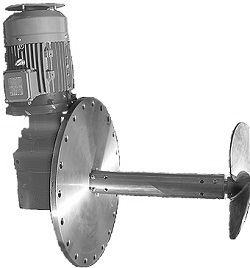

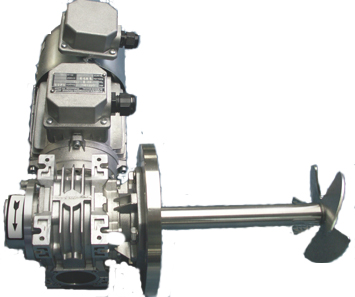

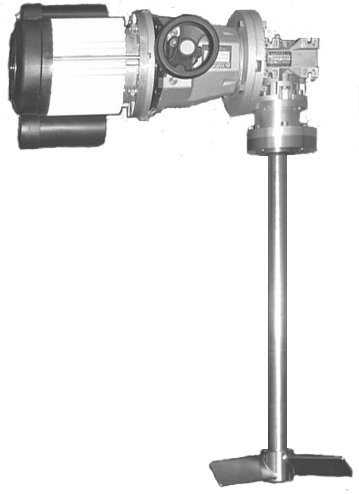

different designs and constructions and sizes

side entry mounting, with double sealing, internal cooling and lubrication fluid and control-viewing tank, with pressure air nozzle and manometer

with shaft protection tube and plain bearing behing the propeller

with shaft protection tube and plain beasring behind the propeller

drivible built ontolifting carriage with container, with counter weight and adjuastable speed

for side entry, with hollow shaft gear, for setting speed with forced ventilation onto the motor

with bearing below, accordance to ATEX, included 2 hand grips

with douple mechanical seal and gear

withseaaling lantern and view control fron the liquid level inside, propeller with sharped lugs and 2 cutting knifes, suitable for dry-run

high setting by hand, with anchor and hollow shaft gear, stand mounted onto grating plate

for high temperatures with crane holder devise, heat protection shield, isolations class H oder höher, bearings with special grease

with hollow shaft gear, speed regulation over hand wheel

Agitators from PRT – So that everything is always well mixed

The chemical industry in particular has to deal with a wide variety of materials and liquids. These must be mixed regularly. This requires special agitators which are not only able to withstand different temperatures but also the different materials. We offer you a wide range of agitators for this purpose, which can be used in different areas. They can be used for simple mixing tasks, gentle mixing, but also for the mixing of strongly foaming media.

Waste water treatment by means of agitators

The possibility of waste water treatment with our agitators is only one of many possible applications. We also differentiate between geared agitators and manual agitators. Of course you also have the possibility to use our agitators in the laboratory to produce different solutions. Our various stirrers are driven by an electric motor, compressed air motor or even a hydraulic motor. They are infinitely variable and thus produce a mixture quickly.

Agitators stand for safety

Our agitators are in most cases also available according to ATEX. In case of explosive materials, our agitators can be used here without any problems. They contain an explosion protection. They are also safe to run dry and can run fast or slow, depending on the agitator. Thus the agitator can be individually adapted to the mixture. A particular advantage of our agitators is their changeability. We offer you a particularly wide range of products, which does not stop at agitators. Also oil separator conveyors, oil skimmers or pumps are part of our product range.

About us and our agitators

We have been in business for over thirty years and know what is important for agitators. We would be pleased to advise you in your search for your agitator and show you the advantages of our products. Whether for small or large companies, we deliver quickly and pay particular attention to quality. Our service is included for you. You can reach us during our business hours by phone, fax and e-mail. You can ask us all your questions, we will be happy to answer them. Rely on the agitator specialist from Herne!