Application

For continuous or discontinuous separation of oil and liquid grease floating on the surface, in patches or continuous layers as a thick layer or wafer-thin films or patches, from cold or hot condensate, neutral to alkaline or acidic in still and highly agitated water.

For groundwater remediation (via deep wells), clarification ponds, coolant emulsions, industrial waste water, oil sumps, harbour facilities, refineries, railway depots, industrial washing plants (for machine parts), pickling plants, oil separators, shipping, degreasing baths in electroplating plants (and metalworking industry), production of food oils and fats, washing plants (for tankers and cars), food industry.

Oils, liquid grease, petrol, paraffin, solvents and similar.

Features

- robust industrial design

- free flying shaft (some sizes with thrust bearing)

- maintenance-free

- extreme steep large-volumed drainage

- clean wiping off

- no oil block in drainage (in usuable viscocity)

- small building compact feature (with large capacity)

- also special construction

Performance range

Functionality

A tension roll holds the belt vertical. Falling out is impossible even if the water has turbulences, wind or if there are solid parts between belt and tension roll.

Oil sticks to both sides of the down moving belt part, transported to top over the driving roll and nearly wiped off dry on down moving belt side, squashing away oil on the inside the belt is impossible with our rolls. Steep drains avoid, in usually viscocity, an oil block or splash over. Oil is quickly drained. Horizontal mounted.

Delivery Dates

Dependend from oil layer thickness, viscosity, belt width, water moving and speed. Rough guidance value at standard speed: belt width in mm = l/h (without obligation).

(see performance curve down)

Construction

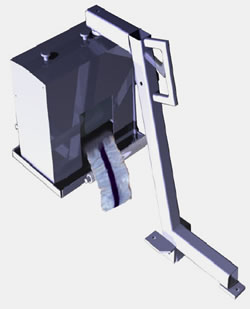

OTF-3 B (total of polypropylene) / OTF-5 B (with gravity discharge)

Special design

Drainage hose ready to fit, pump, adjustable speed, explosion proofed (ATEX), fire damp protection, hydraulic drive, compressed air drive, level switch for oil collecting tank, heatable drains, tension roll safety (for deep vesseln, agitator container or heavy water moving), chute instead of drain for very deifficult or not running recovery slops / greases or others, protection bars against gross dirt parts, belts with skim off bags for floating pollution.

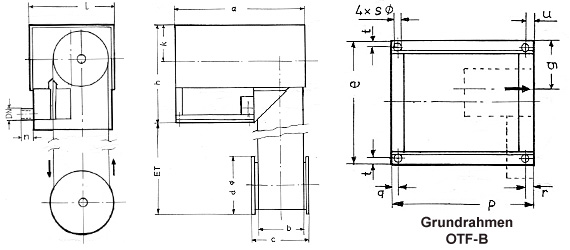

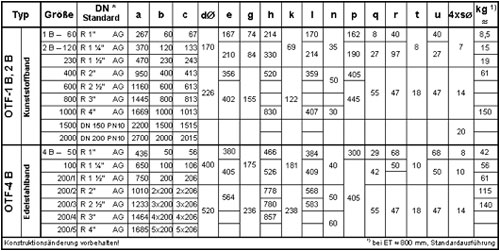

Dimension drawing

* Bigger DN (oil outlet nozzle) are deliverable, if oil has higher viscosity.

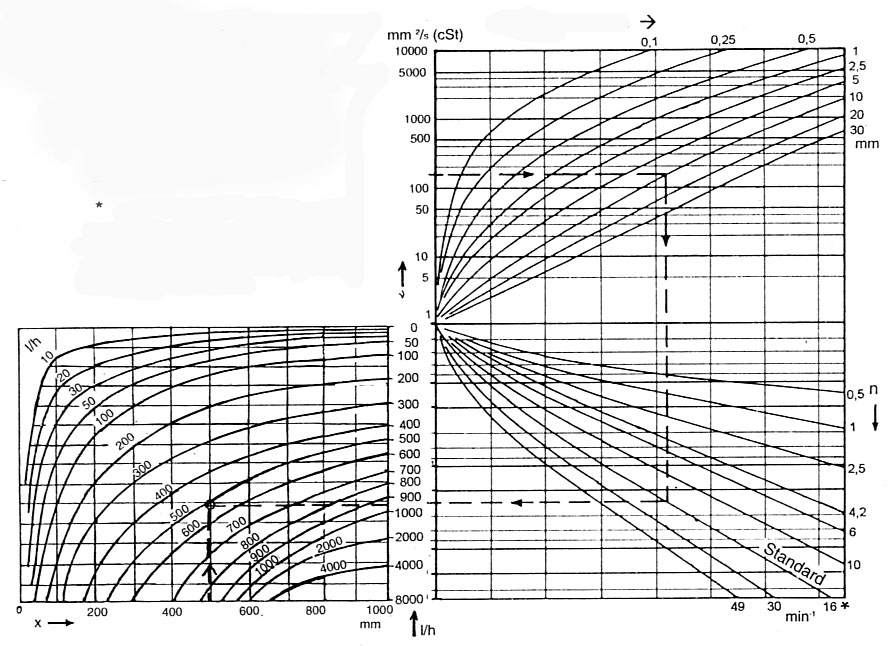

Performance curve

Example to reas perfomance curve:

How much oil in l/h in following operating condition:

Viscosity = 160 mm 2/s (cSt)

Oil layer thickness = 10 mm

Speed = 16 min1

Transporting width dimension x = 500 mm

Redsult: approx. 500 l/h

* 16 min–1 only OTF-2B from size 400 and from size OTF-4B 10 (the 16-min–1 performance curve in accordance about the capacity also for all other OTF-Types in standard speed).

All datas are subjected to alteration!

OTF-3B Oil skimmer with Belt

An oil skimmer developed for applications in the chemical industry where the usual materials of steel, aluminium and stainless steel are not sufficient. Made entirely of polypropylene with polyethylene band. With seal towards the engine compartment.

The shaft is completely sealed and protected. With large-volume and steeply arranged drainage channels. Available sizes, with immersion depths ranging from very short to extremely long.

STEINIG-Oil Skimmer OTF-M (with Mop)

OTF-M…(1) Oil skimmer with Mop

Ölskimmer für große Ölentfernung.

- Several mop widths are available

- Non-binding oil removal rate 80-3,000 l/h

- Immersion depth ET up to 30 m

- Motor in three-phase current, small sizes also in alternating current, also in accordance with ATEX

- Small sizes with oil outlet vertically downwards

- For fixed mounting, for hanging, with tripod or mobile

OTF-M…(2) Oil Skimmer with Mop

Oil skimmer for large oil removal.

- Several mop sizes are available

- Non-binding oil removal rate 80-10,000 l/h

- Immersion depth ET up to 45 m

- Motor in three-phase current, small sizes also in alternating current, also according to ATEX

- Small sizes with oil outlet vertically downwards

- For fixed mounting, for suspension, with tripod or mobile